Press Release

What is the difference between IDC and crimp connectors?

As pioneers in the field of electronic connector solutions, companies like Shenzhen Haiyuncheng Electronic Co., Ltd. are at the forefront of innovation. Specializing in connector design, development, production, and sales, they possess cutting-edge capabilities such as injection molding, terminal stamping, mold design, and a suite of imported precision measuring instruments. These advanced technologies and processes are crucial for manufacturing both IDC and crimp connectors, ensuring that they meet the highest standards of quality and performance.

Electrical connectors are the unsung heroes of modern electronics, ensuring reliable signal and power transmission across countless devices and systems. Among the various connection technologies available, Insulation Displacement Connection (IDC) and crimp connectors stand out as two widely used methods, each with distinct characteristics that make them suitable for different applications.

The primary difference between IDC and crimp connectors lies in their connection mechanisms: IDC connectors pierce through wire insulation to establish contact without stripping, while crimp connectors require stripped wires and use mechanical compression to create a gas-tight connection between terminal and conductor. Both methods eliminate the need for soldering but achieve this through fundamentally different approaches.

Understanding these differences is crucial for engineers, technicians, and procurement specialists working with electrical systems. The choice between IDC and crimp technology can significantly impact product reliability, manufacturing efficiency, and long-term performance in various environmental conditions.

This comprehensive guide will explore:

1. Fundamental working principles of both connection types

2. Mechanical and electrical performance comparisons

3. Application-specific advantages and limitations

4. Reliability considerations for different environments

5. Cost and production efficiency factors

How IDC and Crimp Connectors Work

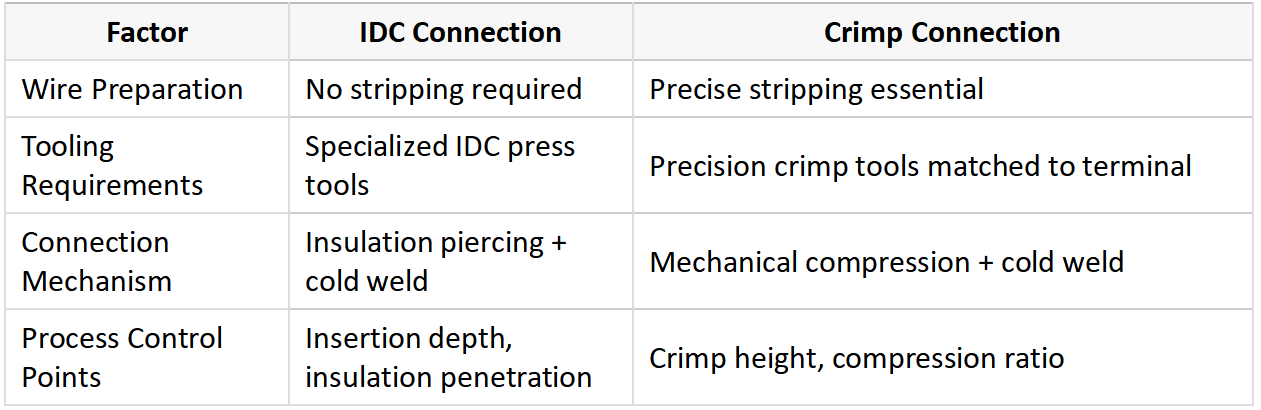

IDC connectors establish electrical contact by forcing a insulated wire into a V-shaped metal slot that cuts through the insulation and makes direct contact with the conductor, while crimp connectors require pre-stripped wires that are mechanically compressed within a metal terminal to form a cold-welded joint.

The insulation displacement technology behind IDC connectors represents a clever solution for mass termination applications. When a wire is pressed into the connector’s V-shaped slot, the sharp edges penetrate the insulation and establish contact with the conductor through a cold-welding process. This method eliminates the need for separate stripping operations, significantly reducing assembly time. The connection quality depends on several factors including insulation hardness, conductor cross-section, and the precision of the terminal geometry. Modern IDC connectors often incorporate strain relief mechanisms to prevent wire pull-out in vibrating environments.

Crimp technology operates on different principles. The process involves inserting a stripped wire into a metal terminal (either machined or stamped) and applying precise pressure to deform both components. This plastic deformation creates a gas-tight interface that prevents oxygen penetration and subsequent oxidation. The crimping process must exceed the wire’s yield point to ensure proper metal flow and permanent deformation. Quality crimp connections show consistent cross-sections when viewed under microscopy, with the conductor strands uniformly compressed and the terminal material flowing around them.

Key process differences:

Performance Comparison: Electrical and Mechanical Characteristics

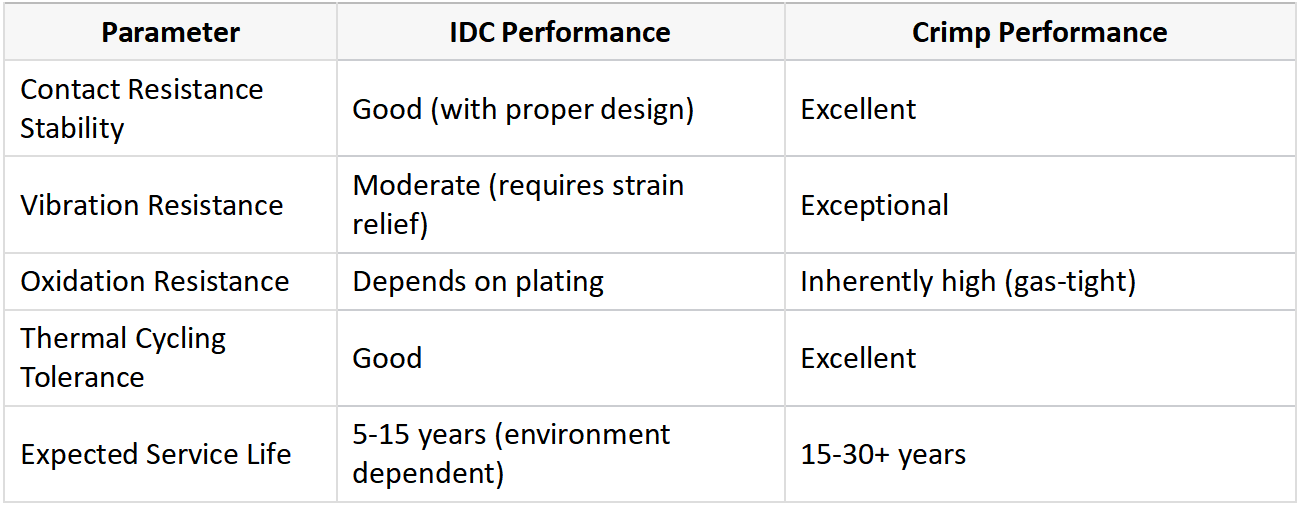

IDC connectors typically exhibit higher contact resistance but are sufficient for signal applications, while crimp connections offer superior conductivity and mechanical strength, making them ideal for power transmission and harsh environments.

Electrically, crimp connections generally outperform IDC in several key metrics. The cold-welded interface of a properly executed crimp creates a metallurgical bond with contact resistance often below 1 milliohm. This makes crimp connections particularly suitable for power applications where current carrying capacity and minimal voltage drop are critical. IDC connections, while electrically adequate for many applications, inherently have higher resistance due to smaller contact areas and potential insulation remnants at the contact interface. However, high-quality IDC designs can achieve stable contact resistance when properly implemented, especially in low-current signal applications.

Mechanically, crimp connections demonstrate superior vibration resistance and wire retention. Automotive and aerospace applications frequently specify crimp connections because they can withstand constant vibration without degradation. The complete encapsulation of conductor strands within the crimp terminal provides excellent strain relief. IDC connections rely more on the insulation clamping force and supplemental strain relief features, which may be insufficient for high-vibration applications without additional securing methods.

Environmental performance differs significantly:

1. Temperature resistance: Crimp connections typically handle wider temperature ranges due to their metallic interfaces, while IDC performance may degrade at extremes

2. Corrosion resistance: Both benefit from plating (tin, gold, silver), but crimp’s gas-tight seal provides better long-term protection

3. Moisture resistance: IDC’s insulation penetration creates potential moisture ingress points absent in crimp connections

4. Thermal cycling: Crimp connections better accommodate conductor/terminal differential expansion

Application-Specific Advantages and Limitations

IDC connectors excel in high-density, rapid-assembly applications like ribbon cable connections, while crimp technology dominates in reliability-critical applications such as automotive wiring and aerospace systems.

The electronics industry has adopted IDC technology extensively for flat ribbon cable connections, particularly in computer and telecommunications equipment. The ability to terminate multiple conductors simultaneously makes IDC ideal for mass termination applications. Modern IDC connectors support conductor sizes from 28 AWG to 14 AWG, accommodating both solid and stranded wires in many cases. Their compact form factor benefits space-constrained designs, and the elimination of stripping operations reduces production time and cost for high-volume manufacturing.

Crimp connections find their strongest applications where reliability cannot be compromised. Automotive wiring harnesses, aircraft systems, and industrial equipment overwhelmingly use crimp technology for its vibration resistance and long-term stability. The technology supports an extremely wide range of conductor sizes (from 0.08mm² to 240mm²) and can accommodate both fine-stranded and solid conductors with appropriate tooling. Crimp terminals also facilitate modular wiring systems, allowing field repairs and modifications that would be impossible with IDC connections.

Industry-specific preferences:

- utomotive: 90% crimp due to vibration requirements; some IDC in interior electronics

- elecommunications: Mixed use – IDC for backplane connections, crimp for field-terminated cables

- onsumer Electronics: Predominantly IDC for internal ribbon cables

- ndustrial Controls: Mostly crimp for reliability; some IDC in control panels

- erospace: Exclusively crimp for maximum reliability

Reliability and Long-Term Performance Factors

Crimp connections generally offer superior long-term reliability due to their gas-tight seal and robust mechanical retention, while IDC connections may degrade over time in challenging environments without proper design precautions.

The gas-tight interface created by proper crimping prevents oxygen penetration, virtually eliminating oxidative degradation at the contact point. This characteristic, combined with the metallurgical bond formed during compression, gives crimp connections exceptional longevity even in harsh environments. Industrial studies have shown properly executed crimp connections maintaining stable resistance for decades in field applications. The mechanical interlock between terminal and conductor also resists vibration-induced loosening, a critical factor in transportation applications.

IDC connections face more reliability challenges due to their fundamental design. The insulation displacement process can leave microscopic gaps where moisture and contaminants may ingress over time. While high-quality IDC connectors incorporate features to mitigate these issues (such as corrosion-resistant plating and insulation-gripping designs), they remain inherently more vulnerable to environmental factors than crimp connections. However, in controlled environments (indoor electronics, sealed enclosures), IDC reliability can approach that of crimp connections for the operational life of most electronic products.

Key reliability indicators:

Production Efficiency and Cost Considerations

IDC technology provides significant cost and time savings in high-volume production environments, while crimp connections offer better field-serviceability and flexibility for low-volume or customized wiring applications.

The economic advantages of IDC become apparent in mass production scenarios. A single IDC termination operation can simultaneously connect multiple conductors in a ribbon cable, achieving termination rates impossible with individual crimps. The elimination of wire stripping further reduces production steps and associated costs. For standardized connections in consumer electronics and office equipment, IDC often delivers the lowest per-connection cost. The technology also requires less operator skill compared to crimping, reducing training costs and quality variability in high-turnover production environments.

Crimp technology, while generally more labor-intensive, offers compensating advantages in flexibility and reparability. The same basic crimp tools can handle various wire sizes and terminal types, making the technology ideal for customized or low-volume production. Field installations and repairs favor crimp connections because they don’t require specialized equipment beyond hand tools. The modular nature of crimp terminals also simplifies inventory management compared to the numerous IDC connector variants needed for different applications.

Cost factor comparison:

1. Tooling Investment: IDC requires dedicated dies for each connector type; crimp tools are more universal

2. Labor Costs: IDC typically lower for high-volume; crimp more efficient for small batches

3. Material Costs: IDC connectors often cheaper; crimp terminals vary widely by quality

4. Rework Costs: IDC connections are difficult to rework; crimp connections easily replaced

5. Quality Control: Both require process control, but crimp parameters are more easily verified

Conclusion

The choice between IDC and crimp connection technologies involves careful consideration of electrical requirements, mechanical stresses, environmental conditions, and production realities. IDC technology shines in high-density, high-volume applications where rapid installation and cost efficiency outweigh ultimate reliability needs. Crimp technology remains the gold standard for mission-critical applications where vibration resistance, long-term stability, and field serviceability are paramount.

Modern engineering often employs both technologies within the same system – using IDC for internal board-to-board connections while relying on crimp for external wiring and power distribution. As connection technologies evolve, hybrid approaches are emerging that combine the best features of both methods, promising even greater reliability and efficiency for future electronic systems.

Understanding these fundamental connection technologies empowers design engineers to make informed decisions that optimize both product performance and manufacturing efficiency. Whether specifying IDC for a consumer electronics assembly or crimp terminals for an aerospace harness, the principles discussed here provide a solid foundation for connection technology selection.

Media Contact

Company Name:Shenzhen Haiyuncheng Electronic Co., Ltd.

City, State, Country:Shenzhen City, Guangdong Province, China.

Address: A building,Baitong science innovation park, No. 150 Shasong RD., Shajing Sub-district

E-mail:sales04@hrb-connector.com

Contact Person: Doria

Website: https://www.hrb-connector.com/

About Author

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Digi Observer journalist was involved in the writing and production of this article.

Press Release

Leman Manhattan Preparatory School Achieves Major Climb in Niche’s 2026 Best Schools Rankings

Recognized for Academic Rigor, College Prep, Arts Excellence and Diverse Community

United States, 15th Dec 2025 — Leman Manhattan Preparatory School, the leading independent, IB World School located in the heart of New York City’s Financial District, is proud to announce it has soared to the top of multiple categories in the 2026 Niche Best Schools Rankings — emphasizing its position as one of the premier K-12 educational institutions in the country.

Leman saw substantial gains in Niche’s key rankings and now holds the following positions among numerous other rigorous, selective independent schools:

- #29 Best K-12 Private School in NY out of 133

- #5 Best High School for the Arts in NY out of 91

- #3 Best Boarding High School in NY out of 30

- #5 Most Diverse Private K-12 School in the NYC Area out of 150

These achievements reflect Leman’s unwavering commitment to academic excellence, student achievement, and preparing students with skills for the future. Leman is uniquely positioned in the New York City independent school market as the only high school boarding school, the only downtown school serving children 12 months to 12th grade, and the only school that achieved student acceptances to all Ivy League colleges within the first 10 years of graduating classes. In addition, Leman student scores on MAP tests have consistently surpassed students at other NY schools for four consecutive years in math, reading and writing.

“Leman’s recognition as a top ranked school is a direct result of the dedication of our exceptional faculty, the academic caliber of our student body, and the strength of our community,” said Maria Castelluccio, Head of School at Leman Manhattan. “Our significant rise in rankings underscores Leman’s high parent and student satisfaction, outstanding outcomes, and reputation as a school that prepares students not only for top universities, but for leadership in a global society.”

Niche’s rankings are based on academic outcomes, program offerings, college interests, student diversity data, and student and parent reviews. Leman’s distinctive education program, which focuses on personalized learning, leadership in extracurriculars and selective college admissions, has experienced increased demand and record retention from families. As Leman enters its third decade, the school is well poised for continuing to meet the needs of high performing students and produce exceptional outcomes.

About Leman Manhattan Preparatory School

Founded in 2005, Leman is an independent, co-educational, college preparatory school that prepares students with the in-demand skills needed for selective college admission and future careers. Leman stands out from other NYC independent schools with its exceptional faculty, IB program, robust arts and athletics offerings, international community, and unparalleled facilities. For more information, contact admissions@lemanmanhattan.org.

Media Contact

Organization: Léman Manhattan Preparatory School

Contact Person: Paige Murphy

Website: https://lemanmanhattan.org

Email: Send Email

Country:United States

Release id:39022

The post Leman Manhattan Preparatory School Achieves Major Climb in Niche’s 2026 Best Schools Rankings appeared first on King Newswire. This content is provided by a third-party source.. King Newswire makes no warranties or representations in connection with it. King Newswire is a press release distribution agency and does not endorse or verify the claims made in this release. If you have any complaints or copyright concerns related to this article, please contact the company listed in the ‘Media Contact’ section

About Author

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Digi Observer journalist was involved in the writing and production of this article.

Press Release

KeyCrew Media Selects Loodmy Jacques as Verified Expert for South Florida Luxury Real Estate and Palm Beach County Housing Markets

KeyCrew Media, a real estate analytics and media network, has selected Loodmy Jacques, leader of The Jacques Team at Keller Williams Reserve, as a KeyCrew Verified Expert.

Baltimore, Maryland, United States, 15th Dec 2025 – KeyCrew Media, a real estate analytics and media network, has selected Loodmy Jacques, leader of The Jacques Team at Keller Williams Reserve, as a KeyCrew Verified Expert. Jacques will contribute data-driven analysis on luxury housing markets, international buyer trends, and real estate market dynamics across South Florida.

KeyCrew Verified Experts are carefully selected as prolific market trend authorities who demonstrate exceptional insight and expertise in their fields. These distinguished professionals regularly contribute market insights, expert perspectives, and forward-looking analysis to help audiences navigate complex industry landscapes.

Loodmy Jacques brings 17 years of specialized expertise to South Florida’s competitive real estate market. Recognized as a top 1.5% agent nationwide by Real Trends 2025, Jacques has built a reputation for serving luxury and oceanfront properties throughout Palm Beach County and Broward County. As the leader of The Jacques Team at Keller Williams Reserve, he provides comprehensive real estate services while also managing a property management division overseeing 80+ homes.

Jacques’ multilingual capabilities—fluent in English, French, and Spanish—position him uniquely to serve South Florida’s diverse international clientele. His deep understanding of cross-border transactions, tax implications, and financing options for international buyers has made The Jacques Team a trusted resource for clients from Canada, France, the UK, and throughout Latin America. The majority of his property management portfolio consists of Canadian investors who have entrusted him with their South Florida assets.

With extensive knowledge spanning markets from Port St. Lucie to Miami Beach, Jacques offers insights into hyper-local market conditions, luxury property trends, and the factors driving South Florida’s continued population growth. His team’s innovative approach combines traditional marketing methods—including distinctive oversized postcards and magazine features—with cutting-edge technology, including AI-generated targeted ads, professional video tours, and advanced CRM systems to provide premier-level service.

“I’m honored to be selected as a KeyCrew Verified Expert,” said Loodmy Jacques. “The South Florida real estate market is incredibly dynamic, with unique opportunities emerging across different price points and communities. Post-election momentum has brought renewed buyer confidence, and with inventory changes and international migration patterns, there’s never been a more important time to provide accurate, localized market intelligence. I’m excited to share insights that help people understand what’s really happening in our market—from the luxury oceanfront properties to emerging opportunities in communities like Port St. Lucie.”

Jacques’ areas of expertise include:

- South Florida Luxury & Oceanfront Real Estate — Specialized knowledge in high-end waterfront properties and ultra-luxury homes across Palm Beach and Broward Counties

- International Buyer Services — Deep expertise serving Canadian, European, and Latin American buyers with multilingual support and cross-border transaction guidance

- Palm Beach County & Broward County Market Dynamics — Comprehensive understanding of hyper-local market conditions, from Delray Beach to Jupiter

- Property Management & Investment Strategy — Proven track record managing 80+ properties for out-of-state and international investors

- Emerging Markets & Growth Areas — Forward-looking analysis of Port St. Lucie and other high-growth South Florida communities

About The Jacques Team

The Jacques Team at Keller Williams Reserve is a premier real estate team specializing in luxury homes, oceanfront properties, and international client services throughout South Florida. Led by top 1.5% agent Loodmy Jacques, the team provides full-service real estate solutions including buying, selling, and comprehensive property management for over 80 homes. With multilingual capabilities and a commitment to Ritz-Carlton-level service, The Jacques Team serves a sophisticated clientele across Palm Beach County and Broward County. Website: www.loodmyjacques.com

About KeyCrew Media

KeyCrew Media is the next generation real estate intelligence platform that leverages AI-powered analytics and first-person reporting from verified experts to produce forward-looking insights across local markets and niche asset classes. Proprietary market reporting is delivered through KeyCrew’s growing portfolio of niche media properties – including KeyCrew Journal, NextAsset News, and other specialized publications – as well as selectively syndicated to media partners that influence industry decision-makers. Learn more at keycrew.co

Media Contact

Organization: KeyCrew Media

Contact Person: Heather Hook

Website: https://www.keycrew.co

Email: Send Email

City: Baltimore

State: Maryland

Country:United States

Release id:38941

The post KeyCrew Media Selects Loodmy Jacques as Verified Expert for South Florida Luxury Real Estate and Palm Beach County Housing Markets appeared first on King Newswire. This content is provided by a third-party source.. King Newswire makes no warranties or representations in connection with it. King Newswire is a press release distribution agency and does not endorse or verify the claims made in this release. If you have any complaints or copyright concerns related to this article, please contact the company listed in the ‘Media Contact’ section

About Author

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Digi Observer journalist was involved in the writing and production of this article.

Press Release

KeyCrew Media Selects ACME Real Estate as Verified Expert for Boutique Brokerage Operations, and LA Market Expertise

KeyCrew Media, a real estate analytics and media network, has selected Courtney Poulos and her team at ACME Real Estate as a KeyCrew Verified Expert.

LOS ANGELES, CA, December 12, 2025 — KeyCrew Media, a real estate analytics and media network, has selected Courtney Poulos and her team at ACME Real Estate as a KeyCrew Verified Expert. The boutique Los Angeles brokerage will contribute specialized insights on renovation-resale strategy, boutique brokerage operations, and LA market dynamics.

KeyCrew Verified Experts are carefully selected as prolific market trend authorities who demonstrate exceptional insight and expertise in their fields. These distinguished professionals and companies regularly contribute market insights, expert perspectives, and forward-looking analysis to help audiences navigate complex industry landscapes.

Founded in 2011 by Broker/Owner Courtney Poulos, ACME Real Estate has established itself as a premier boutique brokerage specializing in renovation-resale projects across Los Angeles. Operating in what Poulos calls “the NFL of real estate,” ACME has built its reputation on comprehensive agent training, ethical accountability, and exceptional client experiences without the backing of international capital funding.

ACME Real Estate offers a distinctive “one-stop shop” approach for real estate investors and renovation-resale specialists. The brokerage provides full-spectrum support from acquisition—including deal analysis and cost-benefit evaluation—through in-house design services at any price point, sophisticated appraisal packaging, and premium marketing. With 35 agents completing 178 transaction sides totaling $155 million in sales volume over the past 12 months, ACME has proven that boutique brokerages can compete against corporate giants through superior training and service.

“We’re honored that ACME Real Estate has been selected as a KeyCrew Verified Expert,” said Courtney Poulos, Broker/Owner. “We built ACME to fill a gap in the market—highly trained agents who the public can trust, comprehensive support for renovation-resale investors, and a commitment to quality over scale. This recognition validates what our clients already know: sometimes the underdogs deliver the highest quality service.”

ACME Real Estate’s areas of expertise include:

- Renovation-Resale Strategy – Comprehensive acquisition analysis, cost estimation, design consultation, and resale marketing for investors

- Boutique Brokerage Operations – Building and scaling quality-focused independent brokerages in competitive markets

- Los Angeles Market Dynamics – Deep expertise in LA neighborhoods, market trends, and investment opportunities

- Agent Training & Development – Mastery-based training programs emphasizing contract expertise and client psychology

- Premium Property Marketing – High-end photography, printed materials, and strategic positioning for maximum market performance

About ACME Real Estate

ACME Real Estate is a boutique independent brokerage founded in 2011 and based in Los Angeles. With 35 agents and 178 transaction sides totaling $155 million in sales volume over the past 12 months, ACME specializes in renovation-resale projects and provides comprehensive support from acquisition through marketing and sale. The brokerage offers in-house design services at any price point, sophisticated appraisal packaging, and premium marketing execution. ACME serves both real estate investors and traditional buyers and sellers with what Broker/Owner Courtney Poulos describes as “the most concierge, attentive, well-trained group of underdogs you could ever have behind you.” Website: https://acmeflorida.com/

About KeyCrew Media

KeyCrew Media is the next generation real estate intelligence platform that leverages AI-powered analytics and first-person reporting from verified experts to produce forward-looking insights across local markets and niche asset classes. Proprietary market reporting is delivered through KeyCrew’s growing portfolio of niche media properties—including KeyCrew Journal, NextAsset News, and other specialized publications—as well as selectively syndicated to media partners that influence industry decision-makers. Learn more at keycrew.co

Media Contact

Organization: KeyCrew Media

Contact Person: Heather Hook

Website: https://www.keycrew.co

Email: Send Email

City: Baltimore

State: Maryland

Country:United States

Release id:39011

The post KeyCrew Media Selects ACME Real Estate as Verified Expert for Boutique Brokerage Operations, and LA Market Expertise appeared first on King Newswire. This content is provided by a third-party source.. King Newswire makes no warranties or representations in connection with it. King Newswire is a press release distribution agency and does not endorse or verify the claims made in this release. If you have any complaints or copyright concerns related to this article, please contact the company listed in the ‘Media Contact’ section

About Author

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Digi Observer journalist was involved in the writing and production of this article.

-

Press Release7 days ago

Circa Watch Labs Revolutionizes Luxury Timepiece Customization With Its Advanced Seiko Mod Builder for Ladies’ Watches

-

Press Release7 days ago

Breaking the mold: CE-LINK Unveils 2400W Balcony Energy Storage System with 2-Minute Self-Installation

-

Press Release6 days ago

Ai Social Marketing Affiliate Pte Ltd AISO Pioneers AI-Driven Creator Monetization, Redefining the Global Content Economy with Blockchain Technology

-

Press Release7 days ago

Best Kratom Brands 2025: Jack Botanicals Dominates Quality Rankings as Industry Reaches New Heights

-

Press Release6 days ago

Kailash Parbat Strengthens Its Presence as Singapore’s Leading Pure Vegetarian Dining Destination

-

Press Release6 days ago

PropertyManagementMalta.co Introduces Full-Service Property Management for Maltese Rentals

-

Press Release7 days ago

Jack Botanicals Revolutionizes Kratom Experience with Breakthrough Quality Standards

-

Press Release7 days ago

Introducing El 9iño: A Unique Voice in Music